Streamline efficiency with specialized mechanical system optimisation support.

Streamline efficiency with specialized mechanical system optimisation support.

Blog Article

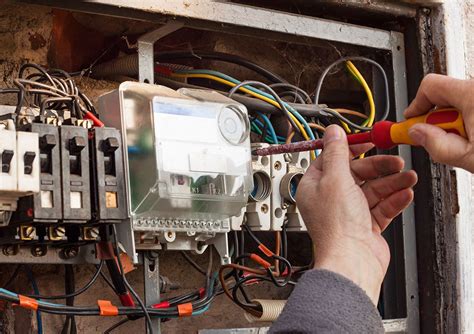

Top Tips for Effective Electric System Troubleshooting

Troubleshooting electric systems calls for a methodical approach, based in an extensive understanding of electric concepts and safety and security methods. By acquainting oneself with circuit components, making use of vital devices, and sticking to a structured analysis technique, specialists can successfully recognize and solve issues. However, the nuances of reliable troubleshooting expand beyond simple technological understanding; understanding exactly how to record searchings for and prioritize security can significantly affect outcomes. As we explore these vital components further, it ends up being clear that understanding this procedure is not simply beneficial but essential for success in the area.

Understand the Basics

Understanding the basics of electric systems is crucial for effective troubleshooting, as a solid structure permits technicians to diagnose and resolve problems more effectively. A thorough understanding of electric principles, such as voltage, current, resistance, and power, is vital in recognizing the origin of troubles. Voltage is the electric potential difference that drives current through a circuit, while resistance opposes the circulation of existing, affecting the overall functionality of the system.

Familiarity with circuit parts, including resistors, capacitors, diodes, and switches over, is likewise paramount. Each element plays a distinct role in circuit habits and can affect performance when malfunctioning. In addition, comprehending collection and parallel circuit configurations is essential, as these arrangements affect the distribution of voltage and present within the system.

Specialists need to be mindful of potential risks, such as shock and brief circuits, to execute risk-free troubleshooting methods. By understanding these fundamental principles, technicians enhance their capacity to conduct effective diagnostics and repair work, eventually leading to enhanced performance and dependability of electric systems (electrical system troubleshooting).

Gather Necessary Tools

Efficient troubleshooting of electrical systems calls for the right collection of devices to diagnose and deal with concerns precisely. Vital tools include a multimeter, which measures voltage, existing, and resistance, enabling for precise analyses of electrical components.

Additionally, shielded hand devices such as screwdrivers, pliers, and wire pole dancers are vital for safely manipulating electric links. It is also suggested to have a circuit tester on hand to validate the visibility of voltage in outlets and cables. For more facility systems, a thermal imaging cam can help identify overheating elements, showing possible failures.

Adhere To a Methodical Strategy

Having collected the ideal tools, the following action in repairing electrical systems is to comply with an organized approach. A methodical strategy ensures that service technicians can determine mistakes efficiently and accurately, minimizing downtime and avoiding unnecessary repairs.

Begin by evaluating the system's schematic diagrams and specifications. Comprehending the layout and functional specifications will provide context for diagnosing concerns. Next off, separate the trouble location by making use of a process of elimination. This involves monitoring each element methodically, starting from the source of power and functioning in the direction of the tons.

Use screening devices, such as multimeters and oscilloscopes, to gather objective data about voltage, current, and resistance at various factors within the system. This empirical proof will guide your troubleshooting efforts and aid to verify or eliminate possible root causes of failure.

Furthermore, think about environmental aspects that may affect the system's performance, such as temperature changes or dampness ingress. An extensive examination of electrical wiring, links, and elements will certainly make sure that all possibilities are accounted for.

Paper Your Findings

Detailed paperwork is crucial in the fixing procedure of electrical systems. Exact records boost the efficiency of determining reoccuring problems and promote communication among group members. Each finding needs to be carefully kept in mind, consisting of symptoms observed, tests carried out, and the end results of those tests. electrical system troubleshooting. This method not just help in understanding the root cause of the issue however also works as a referral for future fixing initiatives.

Additionally, keeping a log of parts replaced or fixings done is invaluable. This details sustains stock management and can aid examine the long life and integrity of particular components.

Inevitably, the paperwork process need to be detailed you can check here yet concise, allowing simple access and evaluation - electrical system troubleshooting. By prioritizing thorough paperwork, specialists can develop a beneficial data base that not only help in current troubleshooting yet likewise encourages future maintenance efforts, therefore enhancing total system dependability

Prioritize Safety And Security Procedures

Recognizing the intrinsic risks related to electric systems is essential for ensuring security during troubleshooting. Electric shock, burns, and tools damage are simply a few of the possible risks that professionals face. Prioritizing Check This Out safety procedures is not just a legal obligation however additionally a moral necessary that safeguards both the technician and the surrounding atmosphere.

Prior to commencing any troubleshooting job, professionals should don proper individual protective devices (PPE), consisting of shielded handwear covers, safety glasses, and flame-resistant clothes. Making sure that the workplace is completely dry and totally free of clutter can significantly minimize the risk of accidents. Additionally, it is vital to de-energize circuits prior to starting any kind of job, validating that they are not endure the use of a multimeter or voltage tester.

Establishing clear communication protocols with employee is also vital; this guarantees that everybody knows prospective risks and the status of the electrical system being worked with. Having an emergency reaction plan in area can confirm important in the event of an incident. see here now By focusing on security steps, specialists can efficiently mitigate threats and promote a safer office.

Final Thought

Reliable electrical system fixing counts on an extensive understanding of essential principles and a systematic method. Focusing on safety steps makes certain the well-being of individuals included and the honesty of the electrical system.

Report this page